|

|

|

CNC

Machining Center |

| CNC precision machinig center

for complete processing - Drilling, Grooving, Routing. Compact design

and high performance technology with through feed technique for cabinets,

furniture, interior design and much more. Compact - Stronger - Faster.

|

|

Features and Benefits |

|

Universal application

in panel processing and solid wood processing |

|

|

Precision

drilling, grooving and routing for efficient panel and solid wood

processing. |

|

Space requirement

3,3 m² |

|

|

The ProTec can be placed at the left side against a wall. |

|

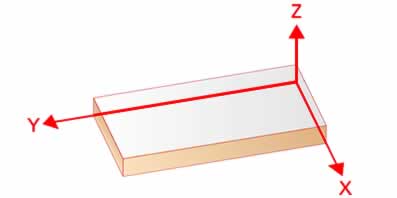

Workpiece dimensions

for the daily practice |

|

|

| • |

Width (X): 60-1300

mm (option) |

| • |

Length (Y):

250-5600 mm |

| • |

Workpiece weight:

max. 75 kg |

Fully automatic workpiece thickness adjustment. |

|

4 side formatting |

|

|

A precise

routing around at all four edges of the workpiece is given and herewith

the full formatting of panel material.

Simply programm the the wished excess length. |

|

Gentle workpiece processing

through air-jets |

|

|

Massive

supporting table with Air-Jet-Table, the most precise and gentle drilling

reference surface. |

|

Vertical drilling

precision

Precision through double laser edge reading |

|

|

The

measuring is done by a laser sensor (touchless workpiece measuring).

The front and rear edges are measured (2-zero-points, double-edge-reading). |

|

Horizontal drilling

precision

Precision through workpiece straightening and the 4th axis at the

drillhead |

|

|

Workpiece

straightening through clamping beams.

The drilling spindle makes the drillling stroke (4th axis at the drillhead)

in this way the workpiece can be drilled in the clamped and straightened

position. |

|

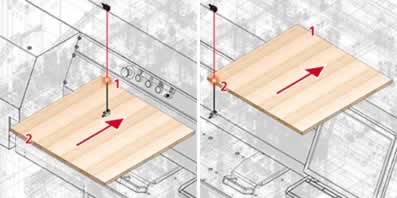

Vertical machining

from underneath |

|

|

Advantages

of the horizontal or lying workpiece transport and processing from

the bottom are:

| • |

The workpiece

weight is spread on the largest workpiece surface, herewith

the relatively thin workpiece edge with the already glued on

edge material is protected. |

| • |

Very easy loading

and unloading of long and heavy workpieces (e.g. countertops). |

| • |

The zero point

is always at the bottom edge of the workpiece. |

| • |

Precise and

constant drilling, grooving and routing depth, even when tolerances

in workpiece thickness are given, because the workpiece is referenced

to the machine steel table. |

| • |

The workpiece

is protected, because the outer surface of the finished workpiece

faces upwards. |

| • |

Chips and sawdust

automatically fall out of holes, grooves and routings, therefore

e.g. clean holes are given for inserting dowels, hinges, fittings

and other hardware. |

| • |

Very good dust

extraction results. |

|

|

Lamello P-System |

|

Advantages of CNC

machines |

|

CNC machines are future-oriented |

|

|

Better

handling of a shortage of skilled workers |

|

|

Companies

with modern equipment keep and retain skilled workers |

|

|

Networking

to CAD designer software and thus digital information flow is possible |

|

|

Several

work steps can be carried out quickly and easily on just one machine |

|

Easy to program |

|

|

Easy

to understand and intuitive software |

|

|

Programming

is easy and can therefore be learned quickly |

|

|

Also

suitable for PC beginners thanks to the simple user interface |

|

|

With

PC knowledge, experience has shown that a good programming basis is

only available in 1 day |

|

CNC drilling + CNC grooving +

CNC routing => everything on 1 machine |

|

|

Further

transport to other machines is eliminated |

|

|

Setup

and modification work are eliminated |

|

|

Great

time savings through the combination of several work steps in just

one work step |

|

|

Workpieces

are ready for assembly |

|

Profitability |

|

|

Even

with a quantity of 1 (batch size 1), even with complex parts |

|

|

Reduced

manufacturing costs through faster processing |

|

|

Reduced

manufacturing costs through no setup times |

|

|

Reduced

use of staff |

|

Flexibility |

|

|

Individual

workpieces - focused on customer requirements |

|

|

No limitations

such as on manual machines |

|

|

Greater

competitiveness and profitability |

|

|

New possibilities

at workpieces - increased production competence |

|

Productivity |

|

|

Increase

in productivity through lower processing times |

|

|

Increases

with the existing workforce |

|

|

Manufacturing

of complex parts quickly and easily |

|

|

Additional

orders e.g. to take from colleagues and implement them on time - made

possible by CNC |

|

Quality |

|

|

Consistent

quality |

|

|

Quality

is independent of the worker |

|

|

Quality

improvement through eliminated sources of error |

|

|

Easier

quality management |

|

Additonal advantages

that will make work easier, reduce set-up time and increase precision,

we will explain to you in a personal conversation |

|